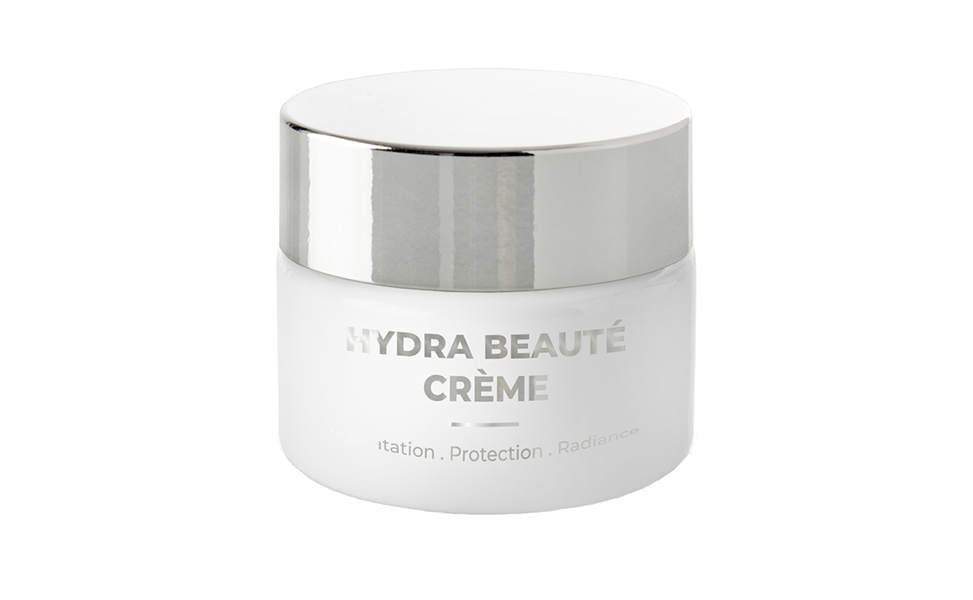

The finishing is the final touch that makes your jar or bottle and its accessory a unique packaging representative of your brand. Your containers can be transparent, lacquered or frosted. There are different finishings possible as silkscreen, pad printing, hot stamping… For your accessories, try aluminium sheatted and logo engraving… Anything is possible!

The finishing is the final touch that makes your jar or bottle and its accessory a unique packaging representative of your brand.

FROSTING

The frosting is a glass attack process to decrease the transparent effect and make it more satiny, opalescent.

LACQUERING

Lacquering on the glass enrichies the appearance by a spray system. The spectrum of colors (gloss, matt, degraded, pearly) is very large.

SILKSCREEN

Silkscreen sprints your decorations by depositing the colors one after the other through silk screens (stencils) on glass or plastic jars and bottles.

PAD PRINTING

Pad printing, applied with an inking pad , allows to bypass printing difficulties.

HOT STAMPING

Hot stamping is the fixing of a gold, silver or metallic ribbon in all colors. Fixing by heat.

METALLIZATION

The metallization, carried out under vacuum by spraying, gives to glass and plastic supports a rewarding metallic appearance. It is easily used for capping systems.

ALUMINIUM SHEATTED

Thanks to the thickness of galvanised and polished aluminium, the sheatted cap and droppers can finalize your most luxurious products.

LOGO ENGRAVING

Logo engraving, applied on a PP or aluminium sheatted cap, identifies your brand immediatly and on a sustainable way.